PVTIME – Crystalline silicon (c-Si) p-type Passivated Emitter and Rear Contact (PERC) solar cell technology currently dominates the photovoltaic (PV) market globally. This is because PERC offers a low-cost, high-efficiency process, with average conversion efficiencies of around 23%. In 2022, the worldwide market share of PERC cells surpassed 90%. Yet the increasing need for clean energy, particularly solar power, necessitates further measures. The solar industry’s path towards high-powered solar panels is illuminated by a range of advanced solar technologies. One such state-of-the-art solution is the Interdigitated Back Contact (IBC) solar cell technology, which has demonstrated superior efficiency using crystalline silicon (c-Si) cells.

During the 6th China International PV Industry Conference held in Chengdu City of China on 13 November 2023, Professor Martin Green of the University of New South Wales expressed his conviction that IBC technology will eventually dominate the photovoltaic solar industry. He stated that “IBC technology will win eventually,” while acknowledging uncertainty about the pace of the technology’s industry-wide adoption. “Whether all companies will switch in five years or whether it’ll take longer, I’m not too sure, but I think everyone will eventually be manufacturing IBC cells.” Professor Martin Green said. Moreover, Professor Martin Green recognized China is acknowledged as the global leader in the solar industry, as many Chinese manufacturers hold numerous records for the highest conversion efficiency of solar cells and modules. However, it remains to be seen if the top players in China are also pioneering in the field of BC technology.

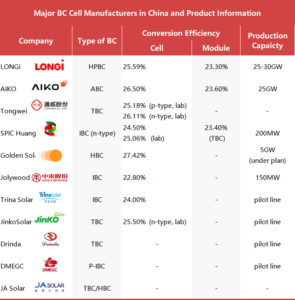

After years of tortuous development, IBC solar cells have undergone significant diversification since their initial conception by Lammert and Schwartz. in 1975. Back contact technology can now be combined with p-type, n-type, or perovskite technology to create various types of cells, including Hybrid Passivated Back Contact (HPBC), Tunneling Oxide Passivated Contact Back Contact (TBC), All Back Contact (ABC), Hetero Junction Back Contact (HBC), and Poly-Si on Oxide (POLO) IBC solar cells.

In September 2023, LONGi, the leader in the photovoltaic industry, declared their dedication to adopting HPBC as their primary technology and product. Mr. Li Zhenguo, LONGi’s founder and president, expressed his anticipation for the increasing popularity of back contact cells over the next five to six years. LONGi’s HPBC cells are expected to set a new standard in the industry, with a conversion efficiency exceeding 25% during mass production. Optimized device structural design enables considerable improvement in light absorption and photovoltaic conversion capabilities, culminating in a substantial surge in power output of the Hi-MO X6 module utilizing HPBC cells. The module achieves a remarkable average conversion efficiency of up to 23.3% in mass production.

In Xiangtan, Hunan province, a distributed PV power plant, using LONGi’s Hi-MO X6 570W mono-facial modules and with an installed capacity of 3.6 MW at Xinhuang Industrial Group, achieved a power yield of 3.97 kWh/kW per day during operations from May to July 2023. This surpassed nearby PV power plants, which utilise dual-facial PERC modules, by 6.54%. Similarly, another rooftop photovoltaic power project at Pourin Special Welding Company (Pourin) in Guangdong Province of China has been generating electricity consistently for almost two months with outstanding outcomes. In October, the project produced 182,300 kWh of power, including 9,884 kWh on a single day, 12 October. This installation, which employs LONGi’s Hi-MO X6 PV modules, generates 4.7% more electricity than a PERC PV module. Now, Pourin uses 40% of their PV power generation for self-consumption, resulting in an impressive saving of 70,000 yuan on monthly electricity costs.

PV Projects using LONGi’s HPBC cells in Hunan and Guangdong Province of China

Another Chinese solar cell producer, AIKO (600732.SH), a professional manufacturer engaged in the R&D, production, sales and service of solar cells, won the Red Dot Product Design Award 2023 for its n-type ABC module. This was the first XBC module that won the award for the amalgamation of advanced technology and aesthetics. The all-black modules installed on buildings create an ultimately elegant appearance along with efficient power generation performance. The ABC module can generate a power output of 460W+ for 54 cells at 2m2 and 610W+ for 72 cells at 2.6m2, with a maximum efficiency of 23.6% in mass production. Compared to current mainstream PERC modules, ABC modules have the potential to increase power output by over 15% throughout their entire life cycle, thereby generating significant market opportunities. AIKO’s XBC showcases maximum conversion efficiency of 24%, whereas in mass production, ABC cells can achieve up to 26.5% according to AIKO.

SPIC Huanghe Hydropower Development Co., Ltd. (SPIC Huanghe), a company primarily involved in small hydro, solar, and wind project development established the first IBC cell mass production line in China. They achieved a 25.06% conversion efficiency on IBC cells in the laboratory and a 24.5% average conversion efficiency in mass production, with a capacity of 200MW. Their latest TBC products combine the dual advantages of IBC and TOPCon technologies, achieving a power output of 460W+ on 2m2 modules, with a conversion efficiency of 23.4%.

Left: AIKO’s ABC modules on rooftop Right: SPIC Huanghe’s IBC and TBC modules

While Trina Solar currently prioritises the production of TOPCon products, it has partnered with the Solar Energy Research Institute of Singapore, a research institution of the National University of Singapore, and the Australian National University (ANU) to conduct research and development related to IBC technology. In 2014, Trina Solar and ANU broke the world record by achieving a conversion efficiency of 24.4% on a small IBC cell. In June 2016, the University of New South Wales in Australia achieved a new conversion efficiency record of 34.5% using Trina Solar’s high-efficiency IBC cells. However, Trina Solar only exhibited a pilot line for IBC products at SNEC 2023 and does not mass-produce them, possibly due to the BC cell’s maximum yield of 95% in mass production, which is lower than TOPCon’s 98%.

Additionally, it cannot be disregarded that the capital outlay required for BC cell production equipment is exceedingly high, approximately double that of the TOPCon production line, and the existence of technological obstacles cannot be ignored.

Will these challenges impede Chinese PV manufacturers toward BC technology? The answer is negative, unless the world ceases to require solar power.

In Tongwei’s performance report for the first half of 2023, it is shown that their research and development of BC technology is setting the pace in the PV industry. Additionally, Tongwei Co.,Ltd. (600438.SH) has successfully developed both p-type and n-type BC, which has resulted in a conversion efficiency of 25.18% with p-type TBC and a peak efficiency of 26.11% with n-type TBC in the laboratory.

Golden Solar New Energy Technology Holdings Limited (Golden Solar, 1121.HK) announced on 6 September 2023 that it has inaugurated the world’s initial mass production line for HBC cells, achieving a conversion efficiency of over 27.0%. In addition, Golden Solar and its partner Gold Stone secured a peak conversion efficacy of 27.42% at their research center. Subsequently, Golden Solar is set to roll out a vast mass production line with a capacity of 5GW of HBC products as the preceding facility is now fully operational.

JinkoSolar has constructed a pilot line for BC cells. Analysis of the measured data leads the JinkoSolar to conclude that the cost differential between BC cells and TOPCon cells shall persist at or above 0.01 yuan/W for the next two to three years. Thus TOPCon will be its core products for next three to five years.

Hainan Drinda New Energy Technology Co., Ltd. (Drinda, 002865.SZ) has initiated its BC technology research since 2022. A pilot line for TBC cells is presently under development and is expected to go into operation by the end of 2023, followed by mass production.

Several other solar cell and module producers in China, including JA Solar, DMEGC, Drinda and Jolywood, are also adopting the BC technology and will pursue further development, research and optimization of related technologies.

Notably, there is a special manufacturer, the world’s trailblazer of IBC manufacturing, Sunpower, which was established in 1985 by Professor Swanson from Stanford University, then spun off its IBC cell production business, along with its IBC patents, to Maxeon Solar Technologies (MAXN.O), who keeps leading position with IBC production capacity of 1.2GW per year in 2014 to 1.5GW in 2023, and conversion efficiency rising from 20.50% in 2004 to 26% in 2022. In 2019, TCL Zhonghuan Renewable Energy Technology Co., Ltd. (TCL Zhonghuan, 002129.SZ), a leading distributor and producer of discrete semiconductor devices in China, acquired part of Maxeon’s share, becoming the largest shareholder of Maxeon with 22.73% shares in 2023. Maxeon maintains its top spot in conducting research and developing IBC cells in the international market.

On 16 November 2023, TCL Zhonghuan issued a statement endorsing Maxeon’s IBC patent infringement dispute against AIKO. Maxeon alleges that AIKO has used its technology and patent No. EP2297788B1, pertaining to “Back-contacted solar cells with doped polysilicon regions separated via trench structures and fabrication process therefor.” This patent relates to proprietary and fundamental solar cell structures for rear or back contact solar cells, commonly known as All-Back Contact (ABC) solar cells or Interdigitated Back Contact (IBC) solar cells.

On the other hand, AIKO has claimed that its ABC products fundamentally differ from the technology safeguarded by the disputed patent, as validated by AIKO’s intellectual property team and a distinguished IP firm situated in Europe. As a world-leading new energy technology company, AIKO is committed to developing state-of-the-art technology and driving innovation within the industry. It places a strong emphasis on protecting our intellectual property rights and pursuing independent innovation. As of 31 October 2023, our company has submitted a total of 1,882 patent applications and acquired 1,061 granted patents. This includes 325 patent applications related to ABC technology, out of which 157 have been approved, creating a comprehensive safeguarding system for our products.

The competition between solar cell producers is likely to continue. Comparisons of various solar cell and technologies are ongoing. It is important to note that products that are popular may not be optimal for everyone. Professor Shen Wenzhong, the head of the Solar Energy Research Institute at Shanghai Jiao Tong University, expressed his personal enthusiasm for HJT products during a ceremony held by LONGi for BC products. In an ideal scenario, two or more mainstream technologies could coexist in the future and may require the cooperation of researchers and producers. Varied client demands will require diversified technologies and products, while the advancement of solar cell and system innovation still has substantial progress yet to be made.

Scan the QR code to follow PVTIME official account on Wechat for latest news on PV+ES

Scan the QR code to follow PVTIME official account on Wechat for latest news on PV+ES